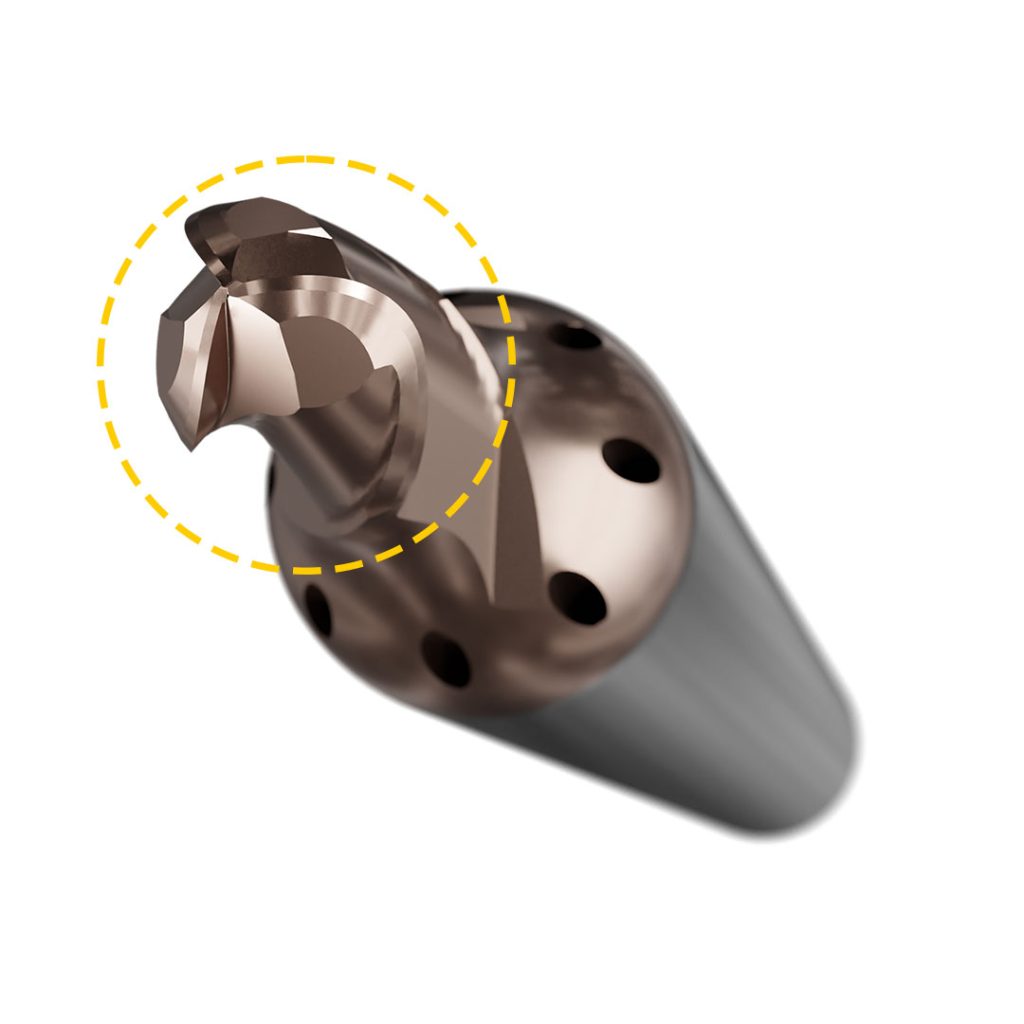

INNOVATIVE COOLANT DELIVERY

The KINGFISHER SERIES features advanced internal and shaft coolant channels that deliver coolant precisely to the cutting edge, ensuring optimal temperature control and efficient chip evacuation:

ENHANCED TOOL LIFE

With innovative geometries and the latest WAD coating technologies, KINGFISHER tools offer superior wear resistance and extended tool life, providing reliable performance and exceptional surface finishes.

VERSATILE MATERIAL RANGE

Designed for machining a variety of difficult-to-machine materials, including titanium, stainless steel, non-ferrous, and precious metals, the KINGFISHER SERIES tools excel in both dry and wet machining environments.

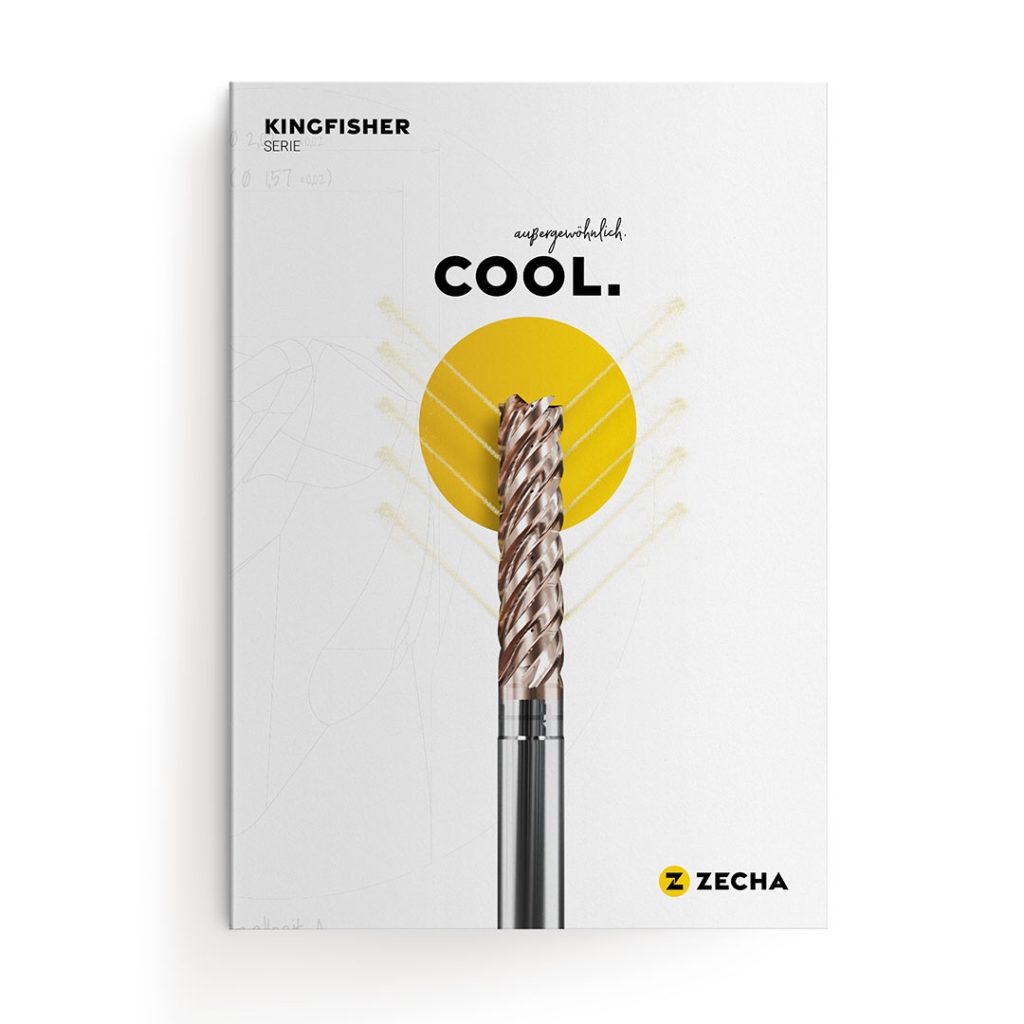

KINGFISHER SERIES

REVOLUTIONARY COOLING FOR PRECISION MACHINING

Welcome to the KINGFISHER SERIES by ZECHA, the pinnacle of innovation in machining difficult-to-machine materials. Building on the success of the proven 455 series, the KINGFISHER tools feature advanced cooling solutions that vastly improve milling operations. Designed for high performance in machining titanium, stainless steel, non-ferrous, and precious metals, these tools offer unparalleled precision and durability. With internal and shaft coolant channels, the KINGFISHER SERIES ensures optimal coolant delivery, reducing wear and enhancing tool life. Experience the cutting-edge technology and superior results that make the KINGFISHER SERIES the ultimate choice for precision machining.

NEXT GENERATION COOLING

Optimized Delivery for Superior Performance

Efficient cooling is vital when working with difficult-to-machine materials such as titanium, stainless steel, non-ferrous, and precious metals. The innovative cooling solutions in the KINGFISHER SERIES minimize the risk of material adhesion to the tool and promote effective chip evacuation through full track grooves. Additionally, the “cold shock effect” on the chips facilitates chip breaking, further improving machining efficiency. By reducing coolant consumption and conserving resources, the KINGFISHER SERIES not only enhances tool life but also boosts overall productivity, making it an indispensable asset for precision machining.

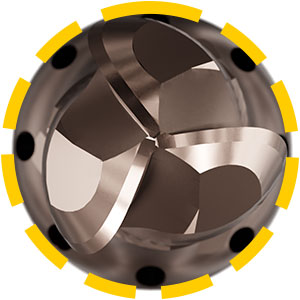

INNOVATIVE COOLANT DELIVERY DESIGN

Bringing Coolant Exactly Where it’s Needed

The KINGFISHER SERIES is equipped with next-generation cooling systems designed to enhance the efficiency and performance of your machining operations. These advanced systems include internal and shaft coolant channels that deliver coolant directly to the contact point between the flute and the material. This precise coolant delivery is crucial for maintaining optimal cutting temperatures, reducing tool wear, and ensuring consistent performance.

SEE THE KINGFISHER SERIES TOOLS IN ACTION

Curious about the KINGFISHER tools’ performance? Click the button below to watch the tools in action milling a demo workpiece out of steel on ZECHA’s YouTube page. See firsthand the exceptional stability, speed, and surface finish these patented tools work with.

OPTIMIZED DESIGN, IMPROVED PRECISION

Enhanced Efficiency and Surface Quality

The KINGFISHER SERIES features an optimized flute design that significantly improves chip evacuation and reduces cutting forces. This advanced design ensures that chips are efficiently flushed away via full track grooves, preventing material adhesion and promoting smoother cuts. The precise, centered flutes contribute to dimensional and geometric accuracy, resulting in superior surface finishes. Whether you are roughing, prefinishing, or finishing, the KINGFISHER SERIES’ optimized flute design delivers exceptional performance and reliability.

MORE EFFICIENT TROCHOIDAL MILLING

Designed for Optimal Machining

The KINGFISHER SERIES is specifically designed for efficient trochoidal milling, a technique that maximizes material removal rates while minimizing heat buildup and tool wear. The advanced geometries and stable cutting edges of KINGFISHER tools enable smooth, consistent engagement with the material, reducing the stress on both the tool and the machine. This design enhances the overall efficiency of trochoidal milling operations, allowing for faster, more precise machining of difficult-to-machine materials.

KINGFISHER PRODUCT TRAINING

Gain a deeper understanding of ZECHA’s tool lines by watching our comprehensive training video. One of our experienced application engineers will guide you through the features and benefits of each tool line in detail. Click the button below to access this valuable resource and enhance your knowledge of ZECHA’s innovative tooling solutions.

KINGFISHER

CASE STUDIES

In addition to the catalog, you can download detailed case studies from the KINGFISHER SERIES. These case studies showcase various milling applications using KINGFISHER tooling, providing in-depth analysis and cutting data for each step. Gain valuable insights into the performance and versatility of KINGFISHER tools across different scenarios. Click the button below to access these informative case studies.

KINGFISHER SERIES CATALOG

Explore the full range of KINGFISHER tools by downloading our detailed catalog. The catalog highlights the key sales points of the KINGFISHER SERIES and provides comprehensive information on all available sizes and geometries. Click the button below to access this essential resource and discover how KINGFISHER tools can meet your precision machining needs.

OPTIONS FROM THIS SERIES

The carousel of tools below showcases the various geometry options available in the KINGFISHER SERIES. Each tool is accompanied by icons that describe compatible materials, tool design details, and other key features. For a comprehensive understanding of these icons and their meanings, refer to the full list available in the KINGFISHER catalog. Discover the perfect KINGFISHER tool for your specific needs by browsing through the options below.

ZECHA Hartmetall-

Werkzeugfabrikation GmbH

Benzstraße 2

D-75203 Konigsbach-Stein

+49 7232 3022-0

info@zecha.de

Contact Page

Cutting Data Calculator

Legal Notice

Privacy Policy

Common Terms of Business

ISO 9001 Certificate