05 November 2020

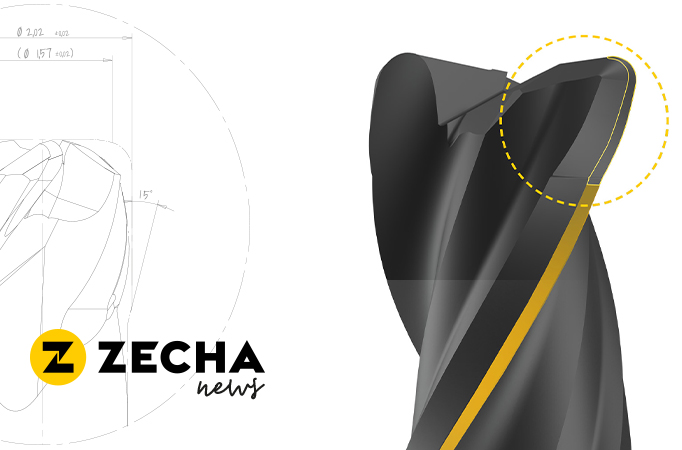

IGUANA

with helix and shaft cooling system 931

ZECHA’s IGUANA line of mill cutters in diverse application-specific versions is known for its specific processing of the cutting edges by means of laser technology (R = 1μm) and special cutting geometry that significantly reduce cutting forces during use.

This results in a lower machining temperature and improved geometrical accuracy. These optimized tool geometries, combined with a sharp and sealed diamond coating, lead to a considerable increase in service life.

In addition, the clusterless tool flutes result in improved surface quality compared to conventional diamond coated tools and provide another benefit in laser processing.

The latest innovation in the IGUANA line combines the special characteristics of the three previous series 912, 918, and 930: torus mill cutters in the 0.5 to 4 mm diameter range with fully sharpened cutting edge, special shaft cooling solution, and spiralization. Compared to series 912 or 930, the new series 931 cutters are more stable, thanks to the shortened design of the basic cutting-edge body and the short flute, to meet the requirements of component production with respect to surface quality and process reliability.

As a main attribute, the sealed high-performance diamond coating in this latest evolution features dual-sided laser-post processing at the relief angle and the cutting face and helix characteristics to allow a softer cut and cleaner circumferential machining. Thanks to laser-processing, this manufacturing process transmits sharp cutting edges, previously achieved with soldered CVD tools, on multi-fluted CVD coated carbide tools without affecting the hardness and strength of the diamond coat and is thus unique in the micro-precision tools sector. High feeds can be achieved in dry and wet machining with the new high-end carbide torus end mills with helix and shaft cooling system: chips are removed optimally from the shear zone with this tool design to reach lower temperature.

ZECHA’s line of mill cutters achieves significantly longer operation times and do no longer require additional tools, which frees up tool spaces for other applications on the machine. The enormous potential of IGUANA tools opens new opportunities for high profitability and maximum productivity.

OTHER ZECHA NEWS:

A trio of experts for the mould making of the future

But how can a supposedly fragile material like ceramic revolutionise the industry? This is precisely the question addressed by this trio of experts – BCE

IGUANA with helix and shaft cooling system 931

ZECHA’s IGUANA line of mill cutters in diverse application-specific versions is known for its specific processing of the cutting edges by means of laser technology

Steadfast with cool precision

Fast, accurate, and water-loving – these attributes aptly describe both the kingfisher bird and ZECHA’s new KINGFISHER line of tools. Based on the existing 455

ZECHA Hartmetall-

Werkzeugfabrikation GmbH

Benzstraße 2

D-75203 Königsbach-Stein

+49 7232 3022-0

info@zecha.de

Cotact Page

Cutting Data Calculator