02 march 2024

ZECHA and LANG Technik:

PEACOCK cutters versus hardened steels

Precision in a double pack: The µm-precise production partnership

Precision in manufacturing doesn’t happen by chance: the µm only works when all components fit perfectly together! For machining centres, this includes zero-point clamping systems and the right vices, such as those from LANG Technik GmbH in Holzmaden.

The company relies on PEACOCK milling cutters from ZECHA Hartmetall-Werkzeugfabrikation GmbH to ensure that nothing is left to chance in their production.

Their role is rarely celebrated, even though it makes a significant contribution to efficient machining processes in the background. Workpiece clamping technology is responsible for the secure and precise fixing of the workpiece and thus for the necessary stability during the machining process. LANG Technik is a global leader in clamping and automation technology. As a manufacturer of high quality innovative products for the machining industry, LANG Technik sees itself as a partner for all those who are looking for flexible and reliable clamping devices for their milling operations: from one-man shows to global corporations, as well as from a broad spectrum of industries such as mechanical engineering, medical tech, aerospace, automotive, motorsport and more.

LANG Technik – fully operational

There is a long list of challenges in modern machining: production processes need to be simplified and made more efficient and manufacturing capacities need to be fully exploited. The focus is also on reducing set-up times and increasing machine utilisation – the ideal arena for LANG Technik’s solutions. Manuel Daiber, Production Manager at LANG Technik, knows what is important here: “Form fit connections are the key to maximum precision. That’s why we at LANG Technik developed our patented stamping technology back then. A separate embossing station is used to create a truncated pyramid shaped blank in just a few seconds which is then reproduced in the clamping system – with huge advantages for the actual milling process.

The highest holding forces, maximum process reliability and exact repeat accuracy are benefits which speak for themselves. Manuel Daiber: “What makes us different is the clamping to just 3mm from the contact surface to the top edge of the vice. This minimises stress on the workpiece and the user benefits from the sustainable use of the material used.”

LANG Technik has 150 employees worldwide, with around 100 in Holzmaden, where the company primarily produces its serial products from zero-point and workpiece clamping technology to automation solutions developed in-house – everything “Made in Germany”.

The challenge: 55-60 HRC steels

When Manuel Daiber switched from automation development to vice production in 2020, he was confronted with very high tool consumption. “The milling cutters really didn’t cost the earth, but as we wanted to produce into the weekend, we needed performance and reliability!” So he started looking for tolls that would allow faster processes in general and simultaneously be able work unmanned from Friday afternoon to Monday morning. Nothing to be sniffed at when mainly hardened steels of 55-60 HRC have to be machined.

“Each component already has a certain production history before it goes into hard machining. If I then produce rejects during the night shift or at the weekend because of a poor or underperforming tool, it costs money. Thanks to ZECHA’S PEACOCK milling cutters, however, I no longer have to worry about this,” reveals Manuel Daiber. A modern CNC machine park, high-end measuring and testing technologies, carefully selected carbides from leading manufacturers and uniform carbide qualities ensure consistent tool quality at ZECHA – a key factor in autonomous series production.

PEACOCK cutters set the pace

The trick was to achieve the highest quality unmanned, reliably and overnight. And that was for a number of demanding machining tasks on the vices. “One ZECHA cutter replaces three other cutters. The amazing thing is I’m four times as fast. And what’s even better is that a single PEACOCK cutter can machine even more components than the three previous cutters combined!” exclaims Manuel Daiber enthusiastically.

ZECHA’s cutting data calculator plays an important role in such impressive results. “It simply gives you values that you can actually run with! As it allows me to run significantly higher feed rates, I’m much faster and I can make four or five times as many parts with consistently good quality – despite the high speed and vast quantities!” In addition, the tools don’t need to be changed prematurely: with cheap cutters, you have to worry about their next performance, with ZECHA’s cutters you can keep on using them without hesitation.

At the same time, idle times are reduced because set-up times are significantly lower.

Well-positioned for hard machining

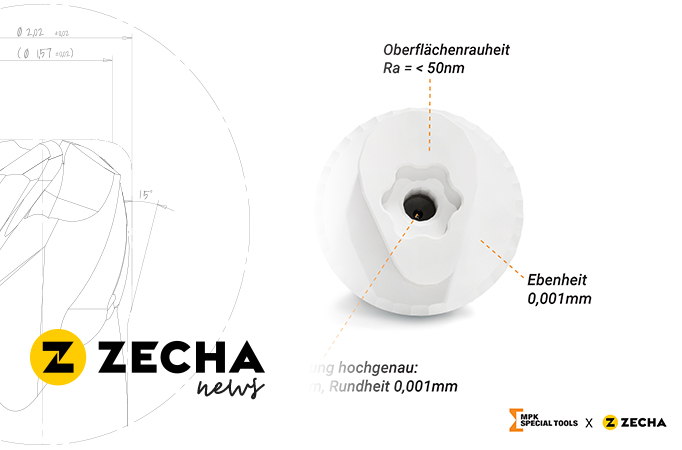

Klaus Bruder, Technical Support at ZECHA Hartmetall-Werkzeugfabrikation GmbH says “Tool concentricity is also an important factor in hard machining. After all, we work with multi-edged tools, so even a hundredth of a concentricity error is theoretically enough to prevent all cutting edges from being used. While this may no be a problem immediately, it certainly will be once the cutting edges wear down, causing problems with both the surface and the tool life. Thankfully, our PEACOCK cutters have form and concentricity accuracies of 0.005mm and 0.003mm respectively.

PEACOCK cutters are designed as special flat peripheral cutters with a high-end WAD coating. For additional cutting edge protection, they have a finely ground protective radius of max. 0.05mm or have defined ground corner radii, depending on the version. This special cutter design scores very highly in terms of performance and wear, therefore offering high machining efficiency for a wide range of materials, alloy components and material hardnesses up to 67 HRC.

Three-point plan for process optimisation

Manuel Daiber remembers the time when production hadn’t yet reached its optimum level: “To be honest, the initial spark really came with the ZECHA moulds because the feed rates we now have would have been impossible before!” But that was not all he achieved together with his colleagues and the expert advice from ZECHA. Manuel Daiber: “Personally, I need any improvement to deliver on three key metrics – more speed, lower costs and easier operation. I’m only satisfied when all three of these points are met and everyone benefits. And by using PEACOCK cutters from ZECHA, we have achieved exactly that and actually gained room for further optimisation!”

OTHER ZECHA NEWS:

ZECHA & ALFATOOL

This partnership draws on the complementary expertise of two specialists in the

field of carbide micro tools. Like ZECHA, ALFATOOL SA specialises in the<br

Ceramic processing

Technical ceramics are very interesting as a material for components with an everincreasing performance. However, their hardness and low toughness make processing extremely difficult.

Generational change at Zecha

Königsbach-Stein – After 25 years at the helm, Reiner Kirschner is bidding farewell to ZECHA Hartmetall-Werkzeugfabrikation GmbH. He has handed over his shares to Yannik

ZECHA Hartmetall-

Werkzeugfabrikation GmbH

Benzstraße 2

D-75203 Königsbach-Stein

+49 7232 3022-0

info@zecha.de

Cotact Page

Cutting Data Calculator