25. OCTOBER 2021

MICRO-SLITTING CUTTER

FROM LETTERING MILLED HAIR TO MICRO-SLITTING CUTTER

Tool manufacturer ZECHA Hartmetall-Werkzeugfabrikation GmbH has shown just how far precision can be taken with lettering milled into a human hair. ZECHA’s sensational 10 micron milling cutter caught the attention of Rohde & Schwarz GmbH & Co. KG in their search to find a unique solution for a special application. In any case, precision is getting to be a substantive issue in the future of communication, information and security.

Rohde & Schwarz has made a name for itself with electronic capital goods for industry, infrastructure operators, and government customers.

With development, production, and marketing of a vast range of products, the technology and market leader is active in the fields of wireless communications and RF test and measurement, broadcast and media technology, air traffic control, and military radio communications, as well as cybersecurity and network technology.

As a pioneer and trendsetter in the field of micro-cutting, stamping, and forming tools, ZECHA produces the ideal tool solution for every application, every material, and every dimension, however small. With origins in the chronograph industry, the expert for micro tools recognizes the importance of precision in various industries. It is not just recently that Rohde & Schwarz has relied on precision tools from ZECHA. Diverse machining solutions have been used here for some time, including high-end multi-cutters in the small diameter range with diamond-coated, laser-sharpened cutting edges in the IGUANA line.

Rohde & Schwarz is one of the world’s largest manufacturers of electronic measurement technology. As a key partner for industry and network operators, they offer a wide range of market-leading solutions for the latest wireless technologies, as well as for RF and microwave applications up to 500 GHz.

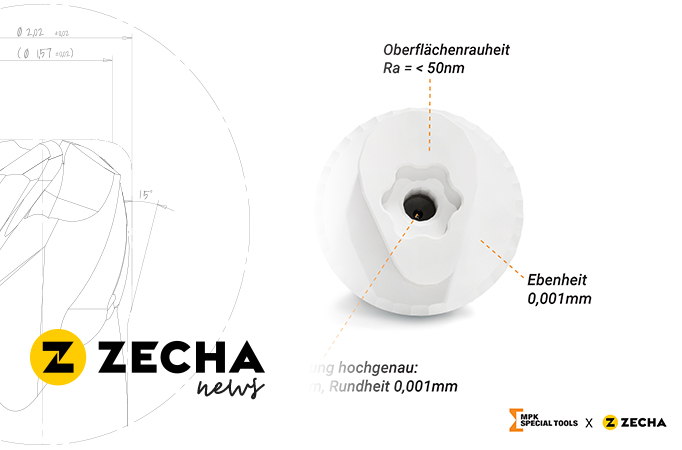

These complex applications demand special solutions. For the creation of a 0.5 mm deep and 0.02 mm wide slit in a brass component, Rohde & Schwarz relied on the expertise of ZECHA. The tool manufacturer designed as special solution a micro-slitting cutter with a diameter of 4 mm and a width of 0.02 mm. To achieve the required even base and optimized cutting performance, a few of the slitting cutter parameters were subsequently improved. Incredible, right?

Together, the two technology experts have made the impossible possible. Through mutual expertise and years of experience in their fields, the problem was handled with an excellent solution. ZECHA and Rohde & Schwarz have been growing with new challenges for decades and are thus constantly offering their customers innovative and unique product solutions.

ZECHA Hartmetall-Werkzeugfabrikation GmbH

OTHER ZECHA NEWS:

ZECHA & ALFATOOL

This partnership draws on the complementary expertise of two specialists in the

field of carbide micro tools. Like ZECHA, ALFATOOL SA specialises in the<br

Ceramic processing

Technical ceramics are very interesting as a material for components with an everincreasing performance. However, their hardness and low toughness make processing extremely difficult.

Generational change at Zecha

Königsbach-Stein – After 25 years at the helm, Reiner Kirschner is bidding farewell to ZECHA Hartmetall-Werkzeugfabrikation GmbH. He has handed over his shares to Yannik

ZECHA Hartmetall-

Werkzeugfabrikation GmbH

Benzstraße 2

D-75203 Königsbach-Stein

+49 7232 3022-0

info@zecha.de

Cotact Page

Cutting Data Calculator