25. JULY 2025

ZECHA & ALFATOOL

An alliance in maximum

micro-precision

expanding its range of high-precision micro-tools through a strategic partnership

with Swiss company ALFATOOL SA. This partnership will see ZECHA take over the

exclusive distribution of ALFATOOL precision tools on the German market – a

significant step towards offering customers an even broader portfolio of top

quality machining solutions.

This partnership draws on the complementary expertise of two specialists in the

field of carbide micro tools. Like ZECHA, ALFATOOL SA specialises in the

development and manufacture of solid carbide precision tools.

exceptionally long service life – manufactured using state-of-the-art CNC machines and innovative production technology. The product range extends from micro milling cutters, engraving milling cutters and roughing milling cutters to drills and circular saws.

A particular highlight of ALFATOOL tools is the wide range of specialised high-

performance coatings, which are specifically tailored to a wide variety of materials and applications:

- TiAlN coating (titanium aluminium nitride, latest generation): A thin,

smooth coating with excellent temperature resistance – ideal for all types of steel and stainless steels as well as titanium and nickel alloys. As a universal coating, it is suitable for both finishing and roughing milling. - STF coating (new): An innovative high-performance coating specially developed for extreme materials such as chrome/nickel steels, stainless steels, titanium and zirconium alloys. It is the coating of choice for particularly demanding materials in precision machining.

- TiCN coating (titanium carbonitride, latest generation): This thin and

smooth coating is perfectly suited for the smooth finishing of all

steels and stainless steels and performs particularly well with tool diameters in the micro range from 0.02 to 0.90 mm. - ALFATOP coating: An extra-thin high-performance coating with an extremely low friction coefficient – specially designed for precious, non- ferrous and abrasive materials such as gold, silver, lead-free brass, copper, aluminium, carbon fibre, mother-of-pearl and various polymers. The coating guarantees perfectly smooth cutting angles, excellent edge sharpness and significantly longer tool life.

‘Thanks to this partnership, we can offer our customers an even wider range of

high-precision solid carbide tools that meet the most demanding requirements,’

stressed Arndt Fielen, Sales Manager at ZECHA. Customers will benefit not only from the expanded product range, but also from a central point of contact and reliable shipping directly from Germany.

Further strengths of ALFATOOL include: Tools are available from stock – with or

without coating – and the standard range covers a wide variety of applications.

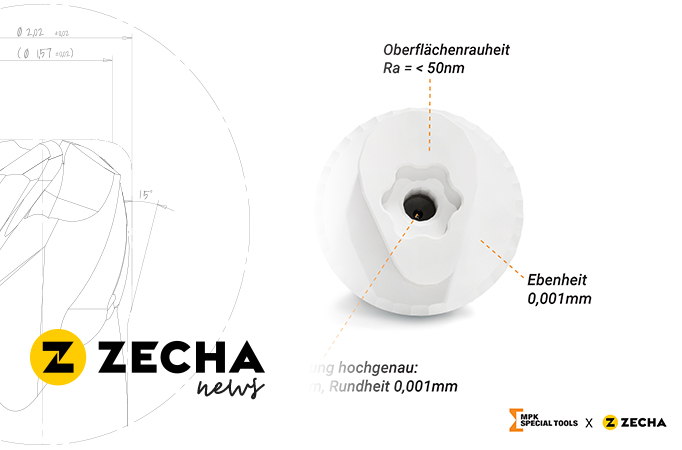

Polished surfaces ensure increased service life, while maximum dimensional and

shape tolerances above the market standard further underline the tools’

performance.

The core range includes micro milling cutters (Z1–Z4), engraving cutters,

reinforced drills (Z2/Z3), cylinder milling cutters and circular saws. The

new ALFATOOL catalogue 2025/2026 is now available – with even greater

choice and detailed technical information on their standard product range.

ALFATOOL SA has had the certification for ISO 9001:2015 since 2016. The state-

of-the-art production facility in Switzerland covers 2,500 m² and underlines the

company’s ongoing commitment to innovation, quality and efficiency.

Thanks to the alliance with ALFATOOL, German customers now have exclusive

access to the highest Swiss quality in the field of micro cutting tools – a

significant added value for demanding industries such as medical technology,

aerospace, automotive, connector technology, defence, watchmaking and

jewellery. Together, ZECHA and ALFATOOL are setting new standards in the world

of micro precision.

OTHER ZECHA NEWS:

A trio of experts for the mould making of the future

But how can a supposedly fragile material like ceramic revolutionise the industry? This is precisely the question addressed by this trio of experts – BCE

IGUANA with helix and shaft cooling system 931

ZECHA’s IGUANA line of mill cutters in diverse application-specific versions is known for its specific processing of the cutting edges by means of laser technology

Steadfast with cool precision

Fast, accurate, and water-loving – these attributes aptly describe both the kingfisher bird and ZECHA’s new KINGFISHER line of tools. Based on the existing 455

ZECHA Hartmetall-

Werkzeugfabrikation GmbH

Benzstraße 2

D-75203 Königsbach-Stein

+49 7232 3022-0

info@zecha.de

Cotact Page

Cutting Data Calculator