15. NOVEMBER 2023

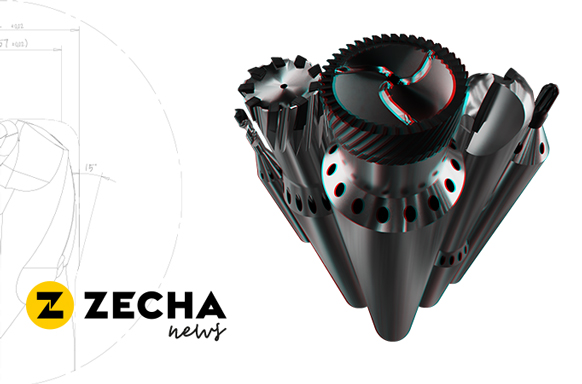

Multi-edged PCD tools

for machining technical ceramics

In recent decades, there has been fundamental change in the world of ceramic materials. The variety of different compositions influence the properties of ceramics depending on their intended use. However, two characteristics make processing these materials especially difficult: their high degree of hardness and their brittleness.

This necessitated the use of complex production methods in the past. Grinding and polishing processes were often employed.

ZECHA has recently developed an innovative solution for exactly this type of material.

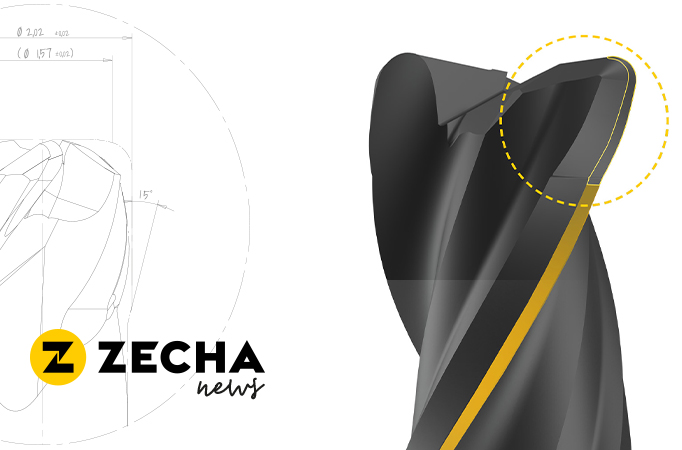

State-of-the-art laser technology is used to create previously impossible tool geometries from ultra-hard cutting materials such as PCD and CVD. Thanks to the use of lasers, these geometries can be designed to be even more delicate, precise and intricate:

In addition, many more cutting edges can be applied to the tool, especially with small tool diameters. A 0.6mm torus cutter with 42 cutting edges is just one example of the many possibilities offered in our 3D-Marlin series brochure.

Successful workshop raises the profile of ceramic milling:

A new approach to micro-machining

In May 2023, ZECHA and its main partners organised a seminar at Teisnach University of Applied Sciences to highlight both the challenges of ceramic machining and the performance of this new generation of tools. In addition to presentations on the material properties of technical ceramics by Teinach University, tool selection by ZECHA, programming by OPEN MIND and machine technology by Röders and WESCHU, there was also a live machining demonstration. A total of 40 participants from 21 companies were particularly impressed by the measurement results from Teisnach University.

- Surface roughness Ra in the nanometre range

- Minimal shape deviations from CAD

- Flatness in the µm range

- Chipping in the µm range

The success story continues: upcoming workshops

In November 2023, another purely ceramic workshop will be held in the Allgäu Regio, once again focusing on micro-machining. Further workshops on this topic are also planned for 2024 in German-speaking areas. The first date for 2024 had already been set and we are delighted to be able to invite you to Bad Dürkheim on 30th January 2024.

ZECHA will be present at the ceramitec trade fair in April 2024 with its own stand in Hall A6. Visit us in Munich and discover the possibilities of our tools for yourself!

ZECHA Hartmetall-Werkzeugfabrikation GmbH

OTHER ZECHA NEWS:

A trio of experts for the mould making of the future

But how can a supposedly fragile material like ceramic revolutionise the industry? This is precisely the question addressed by this trio of experts – BCE

IGUANA with helix and shaft cooling system 931

ZECHA’s IGUANA line of mill cutters in diverse application-specific versions is known for its specific processing of the cutting edges by means of laser technology

Steadfast with cool precision

Fast, accurate, and water-loving – these attributes aptly describe both the kingfisher bird and ZECHA’s new KINGFISHER line of tools. Based on the existing 455

ZECHA Hartmetall-

Werkzeugfabrikation GmbH

Benzstraße 2

D-75203 Königsbach-Stein

+49 7232 3022-0

info@zecha.de

Cotact Page

Cutting Data Calculator