24-hour delivery: Made possible through regional proximity and a close, long-term partnershiph

With an impressive company history spanning more than three decades, KLEINER GmbH has established its name in the field of advanced stamping technology.

Its high quality stamping tools and precision stamped parts from factories in Pforzheim and Eisingen are valued and trusted by companies from a wide range of industries. ZECHA Hartmetall-Werkzeugfabrikation GmbH from Königsbach-Stein is happy to count itself among the supporters of KLEINER as a reliable supplier of micro-precision tools.

“ZECHA is one of our most reliable strategic business partners thanks to its regional proximity and excellent advice,” says Oliver Weissenrieder, Head of Tool Production at KLEINER. KLEINER and ZECHA, a leading manufacturer of high-precision micro-tools, have enjoyed a close relationship since 2011.

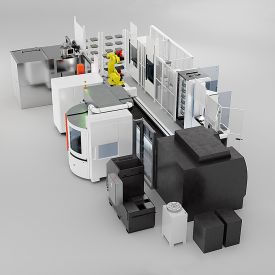

ZECHA’s milling tools are used in KLEINER’s innovative production cells for manufacturing high-precision stamping and moulding tools, ensuring an especially fast overall process thanks to the automated integration of several components. Two HSC milling machines, a die-sinking EDM machine, a cleaning system and optical measuring technology are currently in use here. A 6-axis industrial robot is in the middle of the entire process, controlling production and ensuring assembly. “With the KLEINER production cell, we have laid the foundation for smart production in the spirit of Industry 4.0,” explains Oliver Weissenreider.

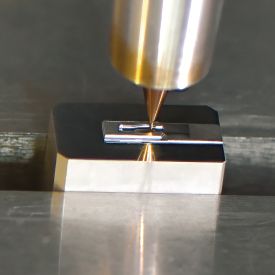

A good example of the smooth interaction between these cutting edge production cell components is the manufacture of an EloPin® embossing system which is used in electromobility. To ensure absolute precision and consistent quality throughout the production process, KLEINER relies on ZECHA’s highly dependable cutting tools. The absolute precision of the manufactured pieces is guaranteed by constant testing from the Alicona µCMM coordinate measuring machine which is perfect for the diffi-cult measurement of materials with particularly shiny and reflective surfaces. “We love the challenge of being able to provide solutions to customer requirements that fall outside of the norm. Our aim is to work together with the customer to provide solutions for special applications with the smallest tolerances as well as demanding production tasks such as the EloPin® embossing system,” explains Klaus Bruder, Technical Support at ZECHA Hartmetall-Werkzeugfabrikation GmbH.

The PEACOCK 599.T2 and 599.B2 series used and specially developed by ZECHA sets new standards in hard machining. The milling cutter’s special flute geometry reduces stress and friction. Thanks to their shank geometry – no sharp edges and cor-ners – stability is increased and a greater milling depth is possible. These robust mill-ing cutters are suitable for dry and wet machining and can also handle the machining of extremely hard-wearing superalloys. “The PEACOCK milling cutters are ideal for automation and demanding applications with long runtimes. Thanks to their high degree of mechanical resilience, they can handle any machining marathon – unmanned, overnight or even over the whole weekend,” says Klaus Bruder.

ZECHA is seen as one of the top innovators in the industry, constantly setting new trends. The partnership means that KLEINER can actively participate in the planning and development of the latest geometries. For example, the company recently presented a ground-breaking series of 3D-layered miniature tools that enable the machining of ultra-hard materials, including carbide, ceramics and glass. With the innovative 3D-layered tools from the MARLIN family, ZECHA is entering a new era, bringing new perspectives to the field of micro-tools and setting new standards in machining.

As a supplier, ZECHA embodies a perfect combination of precision, quality and cost-effectiveness, without ever losing the extreme precision of the miniature tools (+/- 2µm). Thanks to their excellent consultancy, when presented by complex challenges alternatives and customised solutions are always proactively and promptly sought.

KLEINER GmbH Stanztechnik and ZECHA Hartmetall-Werkzeugfabrikation GmbH will have their own stands at the Stanztec trade fair from 25th – 27th June 2024 in Pforzheim.

ZECHA – A MATTER OF TRUST

Precision in our DNA: whether medical or dental technology, watchmaking, automo-tive or tool and mould-making – wherever every “µ” counts – reliable, precise and high-quality tool solutions are essential. ZECHA Hartmetall-Werkzeugfabrikation GmbH has been micro-cutting, stamping and forming tools for a wide range of applications and materials for 60 years. Their extensive and sophisticated tool portfolio boasts excellent surface finishes, the tightest tolerances and long tool life. The highest quality is guaranteed.

ZECHA sees itself as more than just a tool manufacturer: By precisely and specifically analysing the entire process, ZECHA can achieve the best surface qualities in its own production or – when it comes to the component on the machine – at its customers’ premises. Our attention to detail and willingness to change existing processes to optimise them is key here.

Photo 1: From left to right: Christian Jankofsky (Milling Team Leader), Oliver Weissenrieder (Head of Tool Production), Sabrina Weizenhöfer (Linear Cell Team Leader) from KLEINER GmbH Stanztechnik and Klaus Bruder (Technical Support at ZECHA Hartmetall-Werkzeugfabrikation GmbH)

Photo 2: EloPin® embossing system, used in electromobility.

Photo 3: Production cell at KLEINER Stanztechnik – the basis of smart production

For further information:

ZECHA Hartmetall-Werkzeugfabrikation GmbH

Benzstraße 2

75203 Königsbach-Stein

Tel: +49 7232 3022-0

This email address is being protected from spambots. You need JavaScript enabled to view it.

Note to editors:

Text and photos can be ordered from ZECHA

Tel: +49 (0)7232 3022-0 or This email address is being protected from spambots. You need JavaScript enabled to view it.